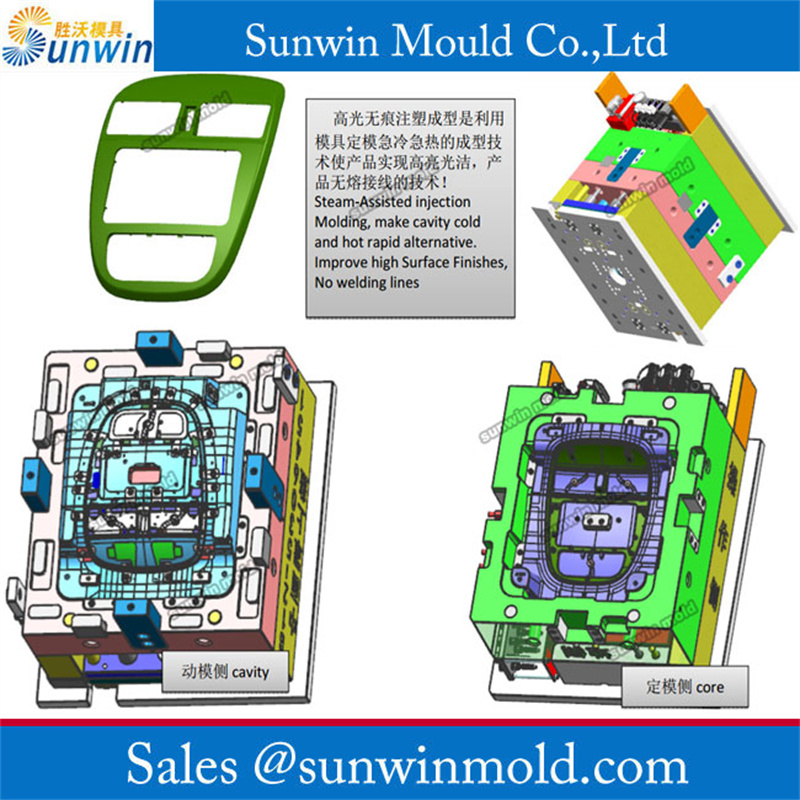

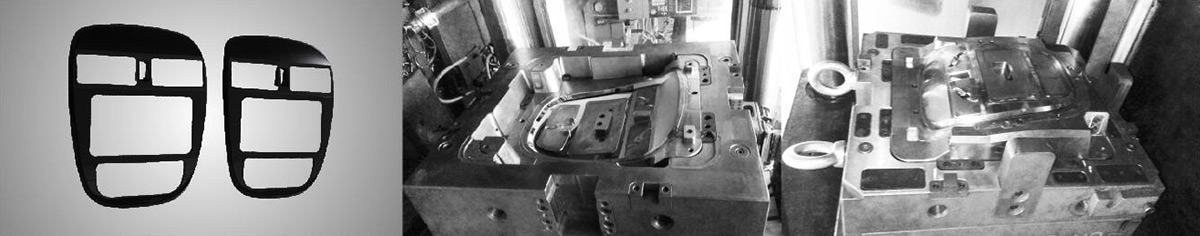

High Gloss Pwm

siab gloss pwm qhia

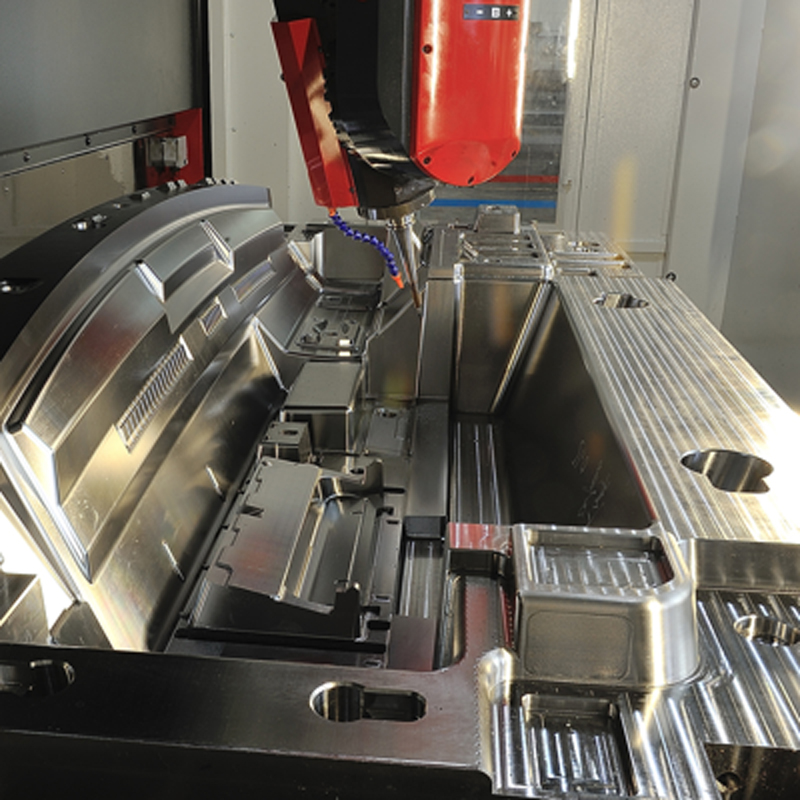

Lub invention nthuav tawm ib tug specular txhaj pwm txais yuav ib tug hluav taws xob cua sov txoj kev, feem ntau aiming ntawm kev daws teeb meem uas tom qab ib tug uas twb muaj lawm ntau-sprue txhaj pwm yog siv, weld marks yog yooj yim generated nyob rau hauv lub nto ntawm ib yam khoom, thiab cov zoo li.Cov pwm txhaj tshuaj tshwj xeeb uas siv cov hluav taws xob cua sov txoj kev suav nrog pem hauv ntej pwm txheej txheem ntawm lub phaj pwm ruaj khov ntawm lub tshuab txhaj tshuaj molding, lub pwm nram qab tau teem rau ntawm cov pwm txav tau ntawm lub tshuab txhaj tshuaj molding, cua sov pwm tub ntxhais, thiab cov phaj txias siv. rau txias txhaj tshuaj molded khoom;ib qho hluav taws xob cua sov caij yog faus rau hauv cov cua sov pwm core.Raws li lub specular txhaj pwm txais cov hluav taws xob cua sov txoj kev, cua sov thiab cua txias yog ntawm nws tus kheej thiab cais tawm, kom lub tshav kub hloov efficiency ntawm pwm yog siab, thiab ntau lawm efficiency ntawm specular txhaj pwm yog ntxiv txhim kho;Tsis tas li ntawd, txoj kev dej hauv lub phaj txias tsuas yog koom nrog hauv kev ua kom txias, kom tsis txhob muaj qhov sib xyaw ua ke, thiab cov qauv ntawm cov pwm yog qhov yooj yim heev.

High lub teeb txhaj tshuaj molding lub ntsiab tsis

Qhov project: Main parameter piav qhia

Pwm kub: Thaum cov pwm yog txhaj molded, qhov kub yog li ntawm 80 ° C-130 ° C, thiab pwm kub yog txo mus rau 60-70 ° C thaum tswj lub siab.Cov kab noj hniav nto yog daim iav polished.Dej vapor cua sov, 3 point koob valve rau hauv cov kua nplaum.

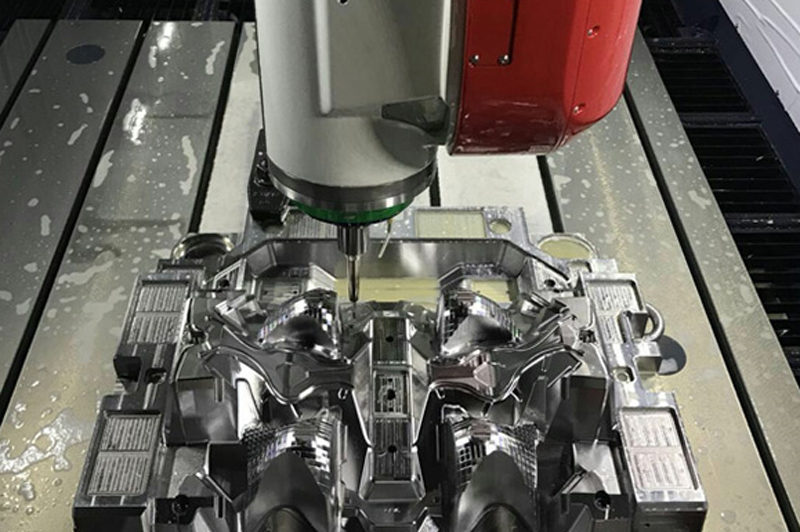

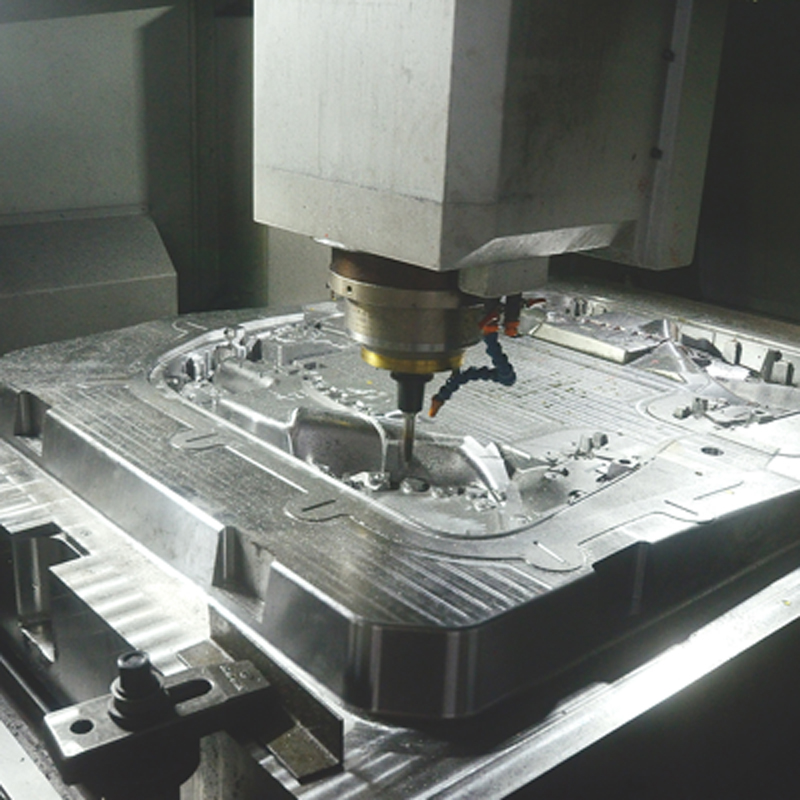

Pwm steel: 1. CPM40/GEST80 (Greitz, Lub teb chaws Yelemees) 2. CENA1 (Datong, Nyiv) 3. MIRRAX40 (Swedish ib yeej 100).

Pwm dej txias: Cov dej channel txais lub qhov taub ntawm 5-10mm, qhov sib nrug yog li 35mm, thiab qhov chaw ntawm cov khoom yog 8-12mm.Lub tshuab hluav taws xob thermocouple yog tsim los tswj qhov kub thiab txias, thiab cov kav dej kub kub yog tsim los ntawm sab tsis ua haujlwm.

Pwm rwb thaiv tsev: Lub dynamic pwm inserts yuav tsum tau hollowed tawm los tsim lub tshav kub rwb thaiv tsev board, pwm thav duab tsim dej txoj kev, daim ntawv qhia kem tsim sab qhia kem, pwm tso 10 hli seem, pwm parting nto sealing nto tsim 10 hli.

Khoom siv

Pwm shipping rau cov neeg siv khoom

FAQ

Q: Koj puas ua pwm rau ntau qhov chaw automtive?

A: Yog, peb ua pwm rau ntau qhov chaw pib, xws li pem hauv ntej nws pib bumper pwm, rov qab pib bumper pwm thiab nws pib grill pwm, thiab lwm yam

Q: Koj puas muaj cov tshuab txhaj tshuaj molding los tsim cov khoom?

A: Yog, peb muaj peb tus kheej kev txhaj tshuaj rhiav, yog li peb tuaj yeem tsim thiab sib sau ua ke raws li cov neeg siv khoom xav tau.

Lus Nug: Koj ua pwm dab tsi?

A: Peb tsuas yog tsim cov pwm txhaj tshuaj, tab sis peb tuaj yeem tsim cov pwm compression (rau UF lossis SMC cov ntaub ntawv) thiab tuag casting pwm.

Q: Nws siv sijhawm ntev npaum li cas los ua pwm?

A: Nyob ntawm cov khoom loj thiab qhov nyuaj ntawm qhov chaw, nws txawv me ntsis.Feem ntau hais lus, pwm nruab nrab tuaj yeem ua tiav T1 hauv 25-30 hnub.

Q: Peb puas tuaj yeem paub lub sijhawm pwm yam tsis tau tuaj xyuas koj lub Hoobkas?

A: Raws li daim ntawv cog lus, peb yuav xa koj cov qauv tsim pwm.Thaum lub sijhawm tsim khoom, peb yuav hloov kho koj nrog cov ntawv ceeb toom txhua lub lim tiam thiab cov duab ntsig txog.Yog li ntawd, koj tuaj yeem nkag siab meej txog lub sijhawm pwm.

Q: Koj yuav lav qhov zoo li cas?

A: Peb yuav xaiv tus thawj tswj hwm qhov project los taug qab koj cov pwm, thiab nws yuav ua lub luag haujlwm rau txhua txoj haujlwm.Tsis tas li ntawd, peb muaj QC rau txhua tus txheej txheem, thiab peb tseem yuav muaj CMM thiab kev tshuaj xyuas online los xyuas kom meej tias tag nrho cov khoom muaj nyob rau hauv kev zam.

Q: Koj puas txhawb OEM?

A: Yog lawm, peb tuaj yeem tsim los ntawm kev kos duab lossis qauv.