Daim ntawv thov ntawm Automotive cov seem muaj qhov tseem ceeb hauv kev txo cov tsheb zoo, txuag roj, txhawb kev tiv thaiv ib puag ncig, thiab rov ua dua tshiab. Feem ntau cov tsheb hluav taws xob yas yog txhaj tshuaj molding. Tsov tawv nqaij tawv nqaij, kev luam ntawv tsis zoo, cov cim dab dej, warping deformation, thiab lwm yam xwm txheej tsis xws hauv kev txhaj tshuaj kho cov khoom molding. Cov tsis zoo no tsis muaj feem cuam tshuam nrog cov ntaub ntawv, tab sis kuj yog cov qauv tsim thiab cov qauv pwm. Nws muaj ntau yam ua nrog cov txheej txheem molding. Hnub no Kuv yuav qhia rau koj qee cov teeb meem thiab cov kev daws teeb meem rau bumper txhaj molding!

1. Siab Kab

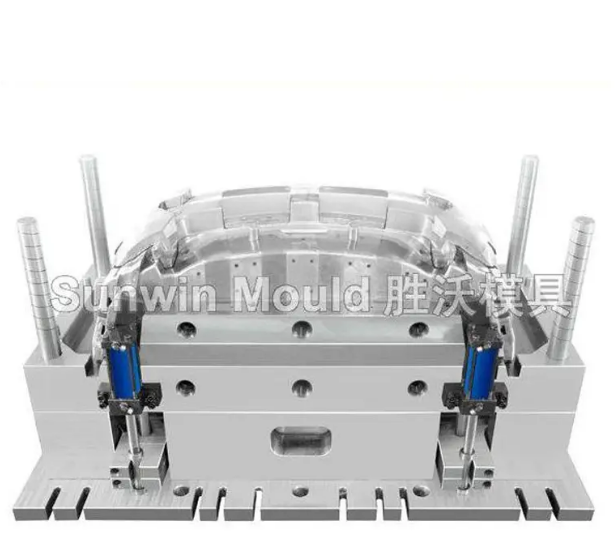

Raws li pom hauv daim duab, muaj cov kab siab pom tseeb nyob ib ncig ntawm lub bumper pos teeb, uas cuam tshuam cov tsos thiab zoo ntawm cov khoom. Txij li lub bumper yog ib feem ntawm sab nraud ntawm lub tsheb, qhov yuav tsum muaj rau qhov zoo yog cov nruj. Qhov tshwm sim ntawm cov kab siab yuav cuam tshuam rau qhov zoo ntawm cov khoom. muaj kev cuam tshuam loj.

1. Cov txheej txheem tseem ceeb ntawm cov ntaub ntawv

Npe: Bumper

Khoom siv: pp

Xim: Dub

Pwm Kub: 35 ℃

Rooj vag Txoj Kev: Koob Valve Rooj vag

2. Muaj peev xwm txheeb xyuas thiab ntsuas kev txhim kho

Xws li nam: nyob rau hauv cov ntaub ntawv no, muaj lub rooj vag g5 ze ntawm lub qhov ib ncig ntawm huab ncig lub teeb. Thaum lub rooj vag qhib, vim hais tias muaj kev cuam tshuam ntawm lub qhov, lub siab ntawm ob sab ntawm lub qhov tau ncav cuag ib lub siab sib npaug dua.

Cov kab siab tau piav qhia nyob rau hauv cov ntaub ntawv yog yeej nyob hauv qab kab, uas feem ntau tshwm sim hauv thaj chaw uas nyob rau thaj chaw Weld. Lub tshuab ntsuas ntawm qhov tshwm sim ntawm cov kab siab siab yog qhia nyob hauv daim duab hauv qab no. Txoj kev daws teeb meem yog sim ua kom txo qis qhov siab sib txawv nyob ib ncig ntawm weld kab, lossis rau lub siab sib txawv tsis txaus txav lub solidifying yaj.

Lub Sijhawm Post: Jan-16-2024