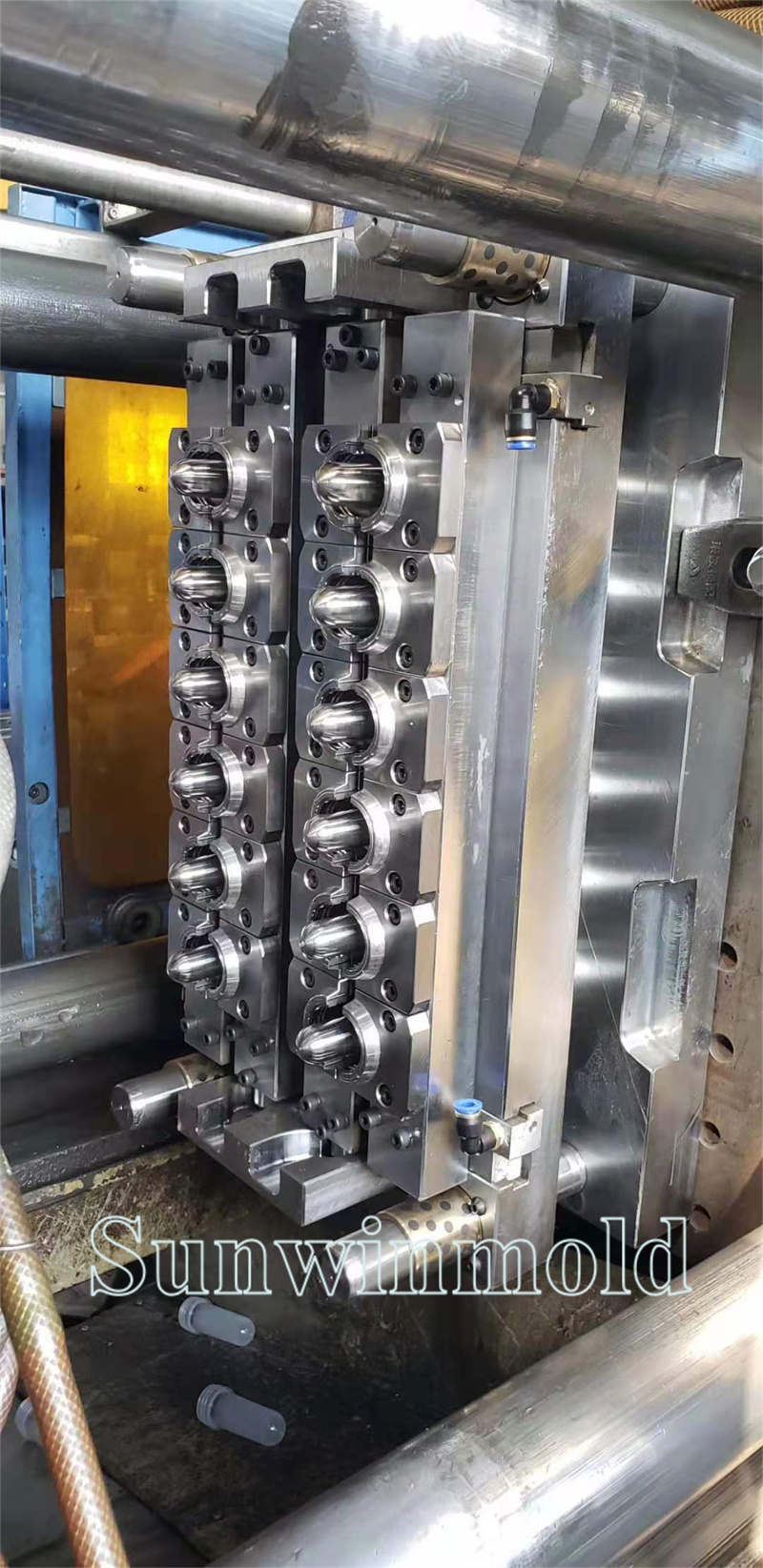

48 Cavity PET Preform Pwm

48-kab kab noj hniav valve PET preform pwm

1. Cov neeg khiav dej kub tau txais kev tswj hwm PID, uas yog tus cwj pwm los ntawm kev kho tsis siv neeg thiab kev tiv thaiv tsis siv neeg, uas tuaj yeem ua rau lub neej ntev ntawm cov khoom siv hluav taws xob cua sov;

-Qhov kub yog tswj nyob rau hauv 1 ° C los xyuas kom meej tias cov ntaub ntawv raw tsis raug kub hnyiab, thiab cov khoom tiav tuaj yeem ncav cuag ntau dua 99%;

-Qhov tshiab nozzle tsim ua rau pwm yooj yim los tswj, qhov thimble ntawm lub nozzle, qhov cua sov, qhov hluav taws xob rwb thaiv tsev, thiab cov thermocouple tuaj yeem hloov tau yooj yim yam tsis muaj kev sib tsoo pwm, uas yog qhov zoo los txo qis qis thiab txuag nqi txij nkawm. .

2. Cua txias system

-Lub kauv kab noj hniav txias dej channel ua rau cov cua txias zog.

-Cov dej txias channel ntawm qhov chaw nres nkoj threaded thiab cov slider txhim kho cov nyhuv txias.

-Exquisitely tsim nruab nrab faib phaj, dej txias tuaj yeem nkag mus rau hauv txhua qhov kab noj hniav, thiab tag nrho cov preforms tuaj yeem ua kom txias zoo sib npaug thiab sai.

3. Kub khiav

- Tus khiav kub nrog kev ua tau zoo sib npaug ua kom cov dej ntws thiab siab ntawm PET yaj hauv txhua qhov kab noj hniav tsis sib xws.

-PET yaj channeling txo qis shear thiab IV poob thiab tso cai rau PET yaj kom ntws sib npaug mus rau txhua qhov kab noj hniav.

- Kev faib hluav taws xob zoo tshaj plaws khaws cov ntsiab lus acetaldehyde (AA) hauv txhua qhov kab noj hniav.khoom

Custom Material 632: Zoo dua FS136 nrog cov ntsiab lus ntau dua nickel thiab chromium.

Toughness, xeb kuj, thiab whitening nyhuv yog obviously txhim kho.

Lub hauv paus pwm yog ua los ntawm HRC 38 ~ 40 stainless hlau los yog P20 (pre-hardened).

2. Cov qauv tsim ntawm SelfLock hom

Ua ntej kaw cov pwm, qhov sib cais seam yog xauv rau hauv qhov chaw los ntawm lub nplhaib xauv kom txo qis kev sib cais ntawm cov kab noj hniav thiab cov tub ntxhais sab, yog li txuas ntxiv lub neej tsis muaj kab mob ntawm txoj kab sib cais.

Taw qhia rau Mould Manufacturing

| Hom | Qhov siab (mm) | Dav (mm) | Thickness (hli) | Qhov hnyav (kg) |

| 6 kab | 650 | 270 | 490 ib | 600 |

| 8 kab | 480 | 360 | 490 ib | 595 ib |

| 12 Kab | 610 | 360 | 490 ib | 755 ib |

| 16 Kab | 740 ib | 360 | 510 | 960 ua |

| 24 Kab | 790 ua | 500 | 510 | 1415 |

| 32 kab | 800 | 580 | 510 | 1600 |

| 48 kab | 1120 | 600 | 560 | 2640 ib |

| 64 cev | 1380 | 600 | 610 | 3545 ib |

| 72 cev | 1170 ib | 800 | 610 | 4 010 |

| 96 cev | 1230 | 960 ua | 610 | 5 050 |

Cov ntaub ntawv saum toj no yog raws li 16g preform nrog PCO caj dab.

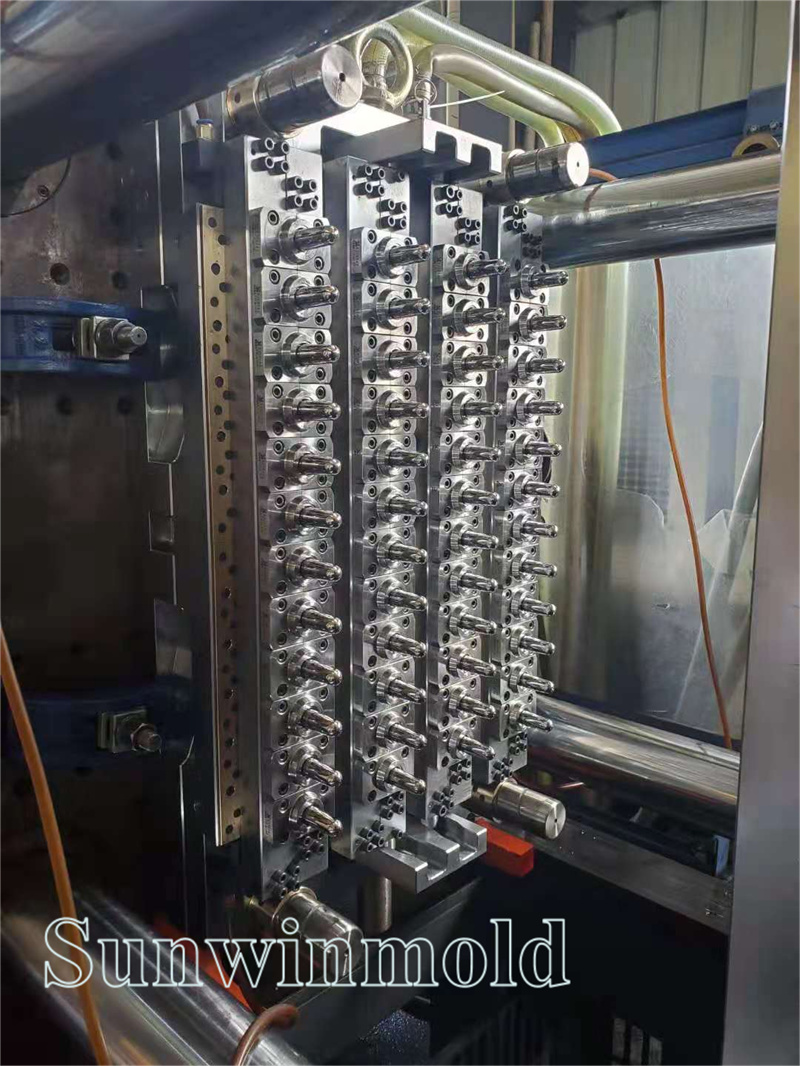

48-kab kab noj hniav air-sealed PET preform pwm

1. Pwm nta:

1. Peb tshwj xeeb hauv kev tsim cov koob valve pwm, uas tsis tas yuav tsum tau txiav kev txiav.

2. Kev siv cov txheej txheem kub ua haujlwm siab ua kom ntseeg tau tias AA tus nqi ntawm cov khoom yog nyob rau theem qis.

3. Tsim nyog cov dej txias channel tsim kom muaj zog txias ntawm cov pwm thiab ua kom lub voj voog txhaj tshuaj molding zoo.

2. Cov khoom siv xaiv:

1. Qhov tseem ceeb ntawm cov pwm yog ua los ntawm cov khoom siv S136 (Sweden-Sabak).

2. Cov khoom siv pwm tau txais cov khoom siv P20 tuaj txawv teb chaws thiab kev kho electroplating, uas txhim kho corrosion kuj ntawm pwm thiab prolongs lub neej kev pab cuam ntawm pwm.

3. Kev kho cua sov ntawm cov khoom yog ua tiav nyob rau hauv lub tshuab nqus tsev vacuum tuaj ntawm lub teb chaws Yelemees, thiab cov hardness ntawm cov khoom yog guaranteed nyob rau hauv HRC45 ° -48 °.

4. Cov cuab yeej ua haujlwm siab heev:

Lub tuam txhab tau tshaj tawm ntau cov cuab yeej siv tshuab tuaj ntawm Tebchaws Meskas thiab Nyij Pooj, xws li cov chaw ua haujlwm, CNC tshuab dhos, EDM, thiab lwm yam, los xyuas kom meej qhov tseeb machining ntawm cov khoom thiab ua rau cov khoom sib hloov tau zoo., qhov hnyav yuam kev tsawg dua 0.3g, 2-5 pwm tuaj yeem tsim nyob rau hauv ib feeb, thiab kev pabcuam lub neej tuaj yeem ncav cuag 2 lab pwm lub sijhawm.

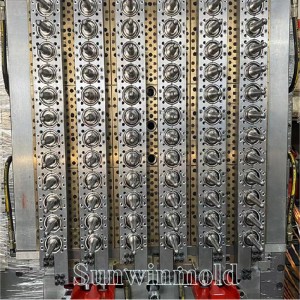

24 kab noj hniav preform pwm

Tus tshiab preform pwm qauv ntawm nws tus kheej tshawb fawb thiab tsim tuaj yeem tshem tawm tag nrho ntawm qhov tsis zoo ntawm cov pwm yav dhau los, thiab tuaj yeem ua tiav high-precision concentricity thiab lub neej ntev ntawm cov pwm, thiab tuaj yeem ua tiav cov qauv ntawm ntau qhov chaw ntawm pwm thiab ntau lawm.Peb cov pwm ua kom ntseeg tau tias phab ntsa thickness sib txawv ntawm lub raj tsis muaj tsawg dua 0.05mm, thiab qhov hnyav yuam kev yog tsawg dua 0.3g.2-5 pwm tuaj yeem tsim hauv ib feeb, thiab kev pabcuam lub neej tuaj yeem ncav cuag 2 lab pwm zaug.Cov pwm muaj qhov siab tshaj plaws ntawm 96 kab noj hniav.

48-kab kab noj hniav air-sealed PET preform pwm

1. Kev tshaj lij thiab kev paub dhau los hauv preform pwm kab noj hniav xws li 1 txog 96 kab noj hniav.

2. Lub preform pwm siv CAD software los tsim lub preform zoo raws li lub raj mis kom paub meej molding zoo ntawm lub raj mis.

3. Cov xov qhib cov khoom ntawm cov pwm preform yog ua los ntawm cov hlau nitrided tuaj txawv teb chaws, tsim raws li cov qauv thoob ntiaj teb, muaj zog hardness, txhua txoj xov yog ventilated, thiab muaj lub neej ua haujlwm ntev yam tsis muaj deformation.

4. Preform pwm core thiab kab noj hniav yog ua los ntawm corrosion-resistant steel, uas yog ruaj.

5. Cov pwm preform txais kev tsim qauv kub khiav, kom txhua qhov kab noj hniav tuaj yeem tswj tau qhov kub ntawm nws tus kheej, rhuab, thiab qhov kub thiab txias tsis sib xws.

6. Txiav-dawb rooj vag preform pwm, txuag kev ua haujlwm thiab cov khoom siv raw.

7. Qhov kub ntawm qhov kub khiav nozzle yog tswj nyias.(Yuav daws qhov teeb meem ntawm kev ntxuav hniav dawb thiab xaim kos duab hauv qab thaum lub sijhawm tsim khoom).

8. Needle-valve self-locking preform pwm: txhua tus tub ntxhais, kab noj hniav, ywj siab muab ob npaug rau nws tus kheej-locking, adjustable eccentricity, txo eccentricity, xyuas kom meej cov khoom concentricity, siab precision.Cov pwm muaj lub neej ua haujlwm ntev.

9. Txhawb nqa cov qauv thiab kos duab ua, muab cov khoom tsim kho tshiab, ib qho kev pabcuam rau kev txhaj tshuaj molding ua!

12 kab noj hniav PET preform pwm

1. Ntshuam S136 steel kab noj hniav, core, thiab threaded caj dab yog siv, thiab kev kho cua sov hardness tuaj yeem ncav cuag HRC 48-50;tag nrho cov formworks yog kub-kho nrog ib tug hardness ntawm HRC 30-35.

2. Advanced pwm tsim tshuab: Txhua kab noj hniav yog nws tus kheej-locking, siv high-precision Japanese SYATEM.Txhawm rau kom ntseeg tau tias lub cev qis thiab qhov tseeb ntawm cov khoom.Txhua qhov tuag muaj cov khoom seem rau cov khoom siv ruaj khov uas tuaj yeem hloov pauv tau.Txhawm rau txhim kho thiab ua tiav kev ua haujlwm siab, peb ib txwm tsim cov cua txias zoo tshaj plaws, thiab tuaj yeem phim lub tshuab cua txias rau txhua pwm.

3. Advanced thiab meej valve kub khiav thiab kub tswj xyuas kom muaj kev ntseeg siab ntawm ntau lawm thiab siab transmittance thiab brightness ntawm cov khoom.

4. Cov pwm zawv zawg yog ua los ntawm tooj liab, lub raj mis lub cev ua tau raws li cov qauv kev nyab xeeb ntawm cov khoom noj, thiab lub neej ntawm cov pwm yog guaranteed ntau tshaj 3 lab lub sij hawm.1.Pwm nta:

1. Peb tshwj xeeb hauv kev tsim cov koob valve pwm, uas tsis tas yuav tsum tau txiav kev txiav.

2. Kev siv cov txheej txheem kub ua haujlwm siab ua kom ntseeg tau tias AA tus nqi ntawm cov khoom yog nyob rau theem qis.

3. Tsim nyog cov dej txias channel tsim kom muaj zog txias ntawm cov pwm thiab ua kom lub voj voog txhaj tshuaj molding zoo.